All Blogs

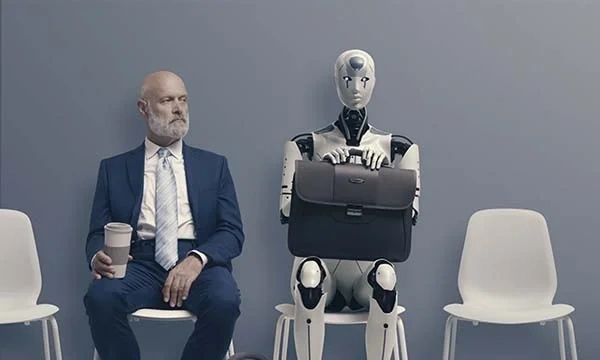

Our Areas of Expertise

With expertise in Digital, Engineering, Cloud and AI, we deliver solutions that fulfill the traditional, transformational and future needs of clients across the globe.

Digital

HCLTech’s end-to-end Digital offerings enable enterprises to increase business resilience, improve operational efficiency and deepen client engagement.

Engineering

HCLTech Engineering and R&D services (ERS) empower enterprises to improve time-to-profit, accelerate product development and maximize return on innovation.

Cloud

HCLTech’s exclusive CloudSMART offerings and services enable organizations to optimize cloud to accelerate innovation and agility at scale.

AI

Building on our engineering heritage, HCLTech has built end-to-end AI capabilities, from chip design to data center optimization to AI applications and models.