GenAI is revolutionizing industrial asset maintenance through ARGiS (Asset Reliability GenAI Suite), an innovative solution that enhances traditional machine learning methods. While conventional machine learning models have demonstrated improved predictive maintenance accuracy, they often struggle to effectively address critical challenges such as alarm interpretation, resolution implementation and knowledge transfer across different assets. ARGiS tackles these challenges by integrating IoT sensor data, historical maintenance records and expert knowledge into a single intelligent platform.

The system's multilingual interface removes technical barriers, allowing maintenance technicians to interact with documentation, troubleshoot issues and record solutions in their preferred language. This post explores ARGiS's solution flow, technical architecture and its transformative benefits for asset reliability and maintenance operations.

Key challenges with asset maintenance

Manufacturing facilities face four primary asset maintenance challenges:

- Reactive quality inspection

Engineers identify tool wear through manual inspection and surface quality checks after machining parts. - Lack of synchronized information infrastructure for the entire plant for site engineers

Lack of real-time updates because IoT integration with machine learning for connected machinery remains underdeveloped. - Lack of infrastructure to maintain new corrective action logs

Manufacturing units struggle to record multilingual logs in a unified platform. - Lack of a digital knowledge base

Complex maintenance manuals delay repairs and increase service costs.

The ARGiS solution addresses the above challenges by providing integrated information and an actionable suite.

Solution components

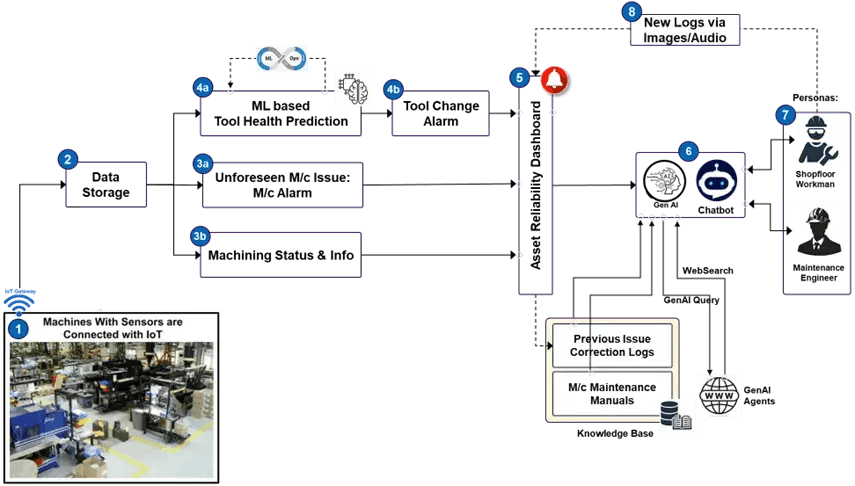

ARGiS solution suite is designed to address the above problems by leveraging ML predictions and infusing GenAI to improve asset reliability. Below are the four pillars of the solution flow:

Figure 1: ARGiS solution pillars

ARGiS process flow

Asset reliability is governed, predicted and maintained based on the live IoT data feed and machine alarms. The process flow includes:

- IoT data collection: Machinery at manufacturing plants continuously transmits operational data, status information and error codes to the IoT system, which stores and monitors this data in real-time.

- Data collection and storage:The live data is collected and stored using IoT-based protocols, providing the foundation for analytics, alerting and further processing.

- Machines’ info and alarms: Machine status, operating conditions and alarms are directly displayed on the dashboard, allowing for user-friendly monitoring.

ML models: An ML-based model is deployed to monitor machine information and predict tool wear. An additional mathematical formulation improves prediction accuracy.

Figure 2: ARGiS process flow

- Asset reliability dashboard: A visual information dashboard consolidates data from all manufacturing plants and assets, alerting users to predicted anomalies or unexpected machine failures.

- GenAI chatbot: Users are provided with an AI-powered chatbot, enabling them to quickly query previous logs, maintenance manuals and web-based resources to resolve issues with minimal downtime.

- User personas: Catering to the needs of both the workman and the maintenance engineer level.

- Logs maintenance for future references: Addition of new logs for recent issue resolutions through audio and hand-written log images supporting multi-lingual capability.

Technical architecture

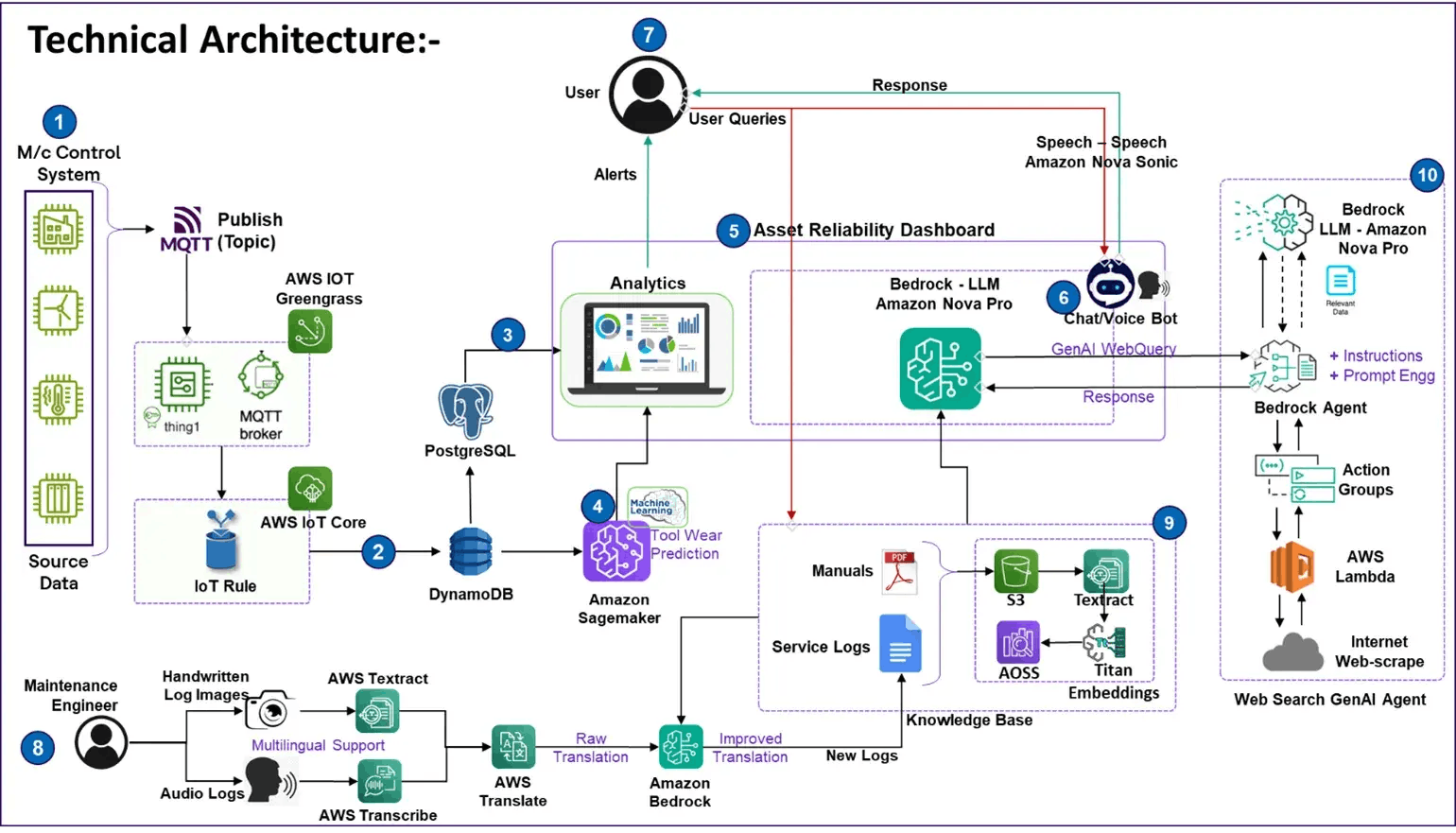

ARGiS uses AWS cloud services and GenAI technology. The diagram below shows its technical architecture:

Figure 3: ARGiS technical architecture

- M/C control system data flow: Machine control systems (IoT sensors, Industrial controllers, Machine status indicators/alarms) continuously generate operational data. The data is formatted into MQTT messages and published to specific MQTT topics. AWS IoT Greengrass acts as an MQTT broker and processes and further transfers data to AWS IoT Core.

- Data collection – AWS DynamoDB: AWS's NoSQL database service (DynamoDB) is leveraged to store the IoT device data after processing, providing a scalable database for time series and event data.

- PostgreSQL: A relational database used for structured data storage, likely handling more complex queries and relationships in the system.

- ML tool wear prediction: ML model deployed on Amazon Sagemaker analyzes machine data to predict when tools or equipment may fail, enabling predictive maintenance.

- Asset reliability dashboard: A visualization interface showing analytics about machine performance, reliability metrics, and alerts to help monitor the overall health of assets.

- Voice Bot: An interface using Amazon Nova Pro voice services to enable spoken interactions with the system.

- M/C alarm assist: Natural language-based conversational interface enables machine operators to interact with the knowledge store to fix machine alarm issues. Below are the core components of this flow:

- Alarm reception: The component receives alerts when anomalies or potential failures are detected in the machine systems.

- User query interface: Allows operators to query the system about alarm details, historical patterns and recommended actions through Text-based queries or Voice interaction leveraging speech-to-speech capabilities (Amazon Nova Sonic) powered by Amazon Bedrock.

- Contextual response: Provides responses with relevant information about root cause analysis, Similar historical incidents, recommended troubleshooting steps, expected impact on production, etc.

- Log maintenance: This solution component represents the maintenance Engineer workflow for log processing and integration. This system handles various maintenance logs and transforms them into structured, searchable data within the knowledge base. Below are the core components of this module:

- Multiple log input types

- Handwritten log images: Physical maintenance logs, inspection sheets, or notes captured as images.

- Audio logs: Voice recordings of maintenance activities, observations, or verbal reports.

- Multi-modal processing pipeline:

- Handwritten logs route through AWS Textract for text extraction from images.

- Audio logs flow through AWS Transcribe to convert speech to text.

- Multi-lingual support:

- AWS Translate handles initial "Raw Translation" of non-English content.

- Amazon Bedrock provides "Improved Translation" with more contextual accuracy for technical terminology.

- Multiple log input types

- Knowledge base – knowledge preservation:

- Processed logs are added to the Knowledge Base, alongside the stored and processed machine manuals and user guides.

- The Amazon Titan Text Embedding model converts text into vector representations (embeddings) for semantic search.

- AOSS (Amazon OpenSearch Serverless) indexes this content for searchability for future maintenance.

GenAI agents:

Amazon Bedrock agent is built with two action groups. The first action group enables the agent to web scrape a specific URL provided by the user (if any), while the second action group allows the agent to perform an internet search based on a user query without requiring a URL.

This gives the users (line managers/service engineers) quick access to the most relevant public information on the Internet.

This AWS-based IoT/GenAI architecture provides exceptional scalability through serverless components and managed services (AWS Lambda, Amazon DynamoDB, Amazon Bedrock), robust data security via AWS's built-in encryption and access controls and comprehensive operational resilience through edge computing (Greengrass) combined with cloud processing.

Benefits

- Proactive troubleshooting: Empower reliability engineers to rapidly identify root causes of failures and provide maintenance teams with actionable recommendations to minimize downtime.

- Optimized operations: Provide engineers and maintenance teams instant access to ideal operating conditions, streamlining their decision-making process and ensuring optimal system performance.

- Data-driven maintenance: Enable maintenance and operations teams to analyze maintenance records and a comprehensive knowledge base to gain valuable insights, driving improvements in asset reliability, efficiency and overall system performance.

- Multilingual logging solution: Offer maintenance engineers and workers the ability to log new issue resolutions into the system with minimum effort for future reference.

Conclusion

ARGiS addresses critical Industry 4.0 challenges like unplanned downtime and production interruptions by:

Transforming reactive maintenance into proactive solutions

Leveraging AWS serverless architecture for enterprise-grade scalability

Providing end-to-end encryption for data security

Enabling seamless multi-site deployment

Preserving technical expertise for future use

This solution helps organizations achieve manufacturing excellence through increased equipment reliability, optimized resource allocation and maintained institutional knowledge.

Is your organization ready to revolutionize asset management with GenAI? ARGiS can transform maintenance operations, reduce downtime, and optimize resource allocation.

See the power of ARGiS firsthand:

- Request a personalized demo

- Explore how ARGiS can address your specific challenges

- Learn about seamless integration with your existing systems

Don't let outdated asset management hold you back. Take the first step towards Industry 4.0 excellence today.

Contact us for a demo: Email: AWSEcosystemBU@hcltech.com

Transform your asset reliability strategy with ARGiS – where AI meets industrial expertise.