Exploring trends, challenges and strategic solutions

Understanding the impact of changing market conditions on the automotive value chain is crucial for strategic planning. In the short term, various factors can disrupt supply chains, increase costs and affect pricing strategies. It's essential to analyze how these changes influence stakeholders, from manufacturers to consumers.

Trends and opportunities

The automotive aftermarket is experiencing significant trends that present challenges and opportunities. Here are some key trends:

Higher costs for imported parts

The rising costs of imported parts could squeeze profit margins unless these costs are passed on to customers or renegotiated with suppliers. Recent data indicates that cost increases can be upwards of $6,000, compressing margins by 15-30%.

Shift in consumer behavior

As new car prices increase, consumers are buying fewer new vehicles. This leads to a higher demand for repairs on older vehicles, which can enhance revenue streams for service providers. Repair costs are expected to rise by 25%, boosting the aftermarket sector.

Supply chain disruptions

The dependence on a global supply chain introduces risks of delays or shortages, potentially affecting service delivery times. This disruption can decrease sales volume by 25%, highlighting the need for more resilient supply chain strategies.

Competitive pressure

As repair costs rise, the insurance industry's ripple effects can further increase competition and margin pressure. Service providers must navigate these dynamics effectively to remain competitive.

Strategic solutions

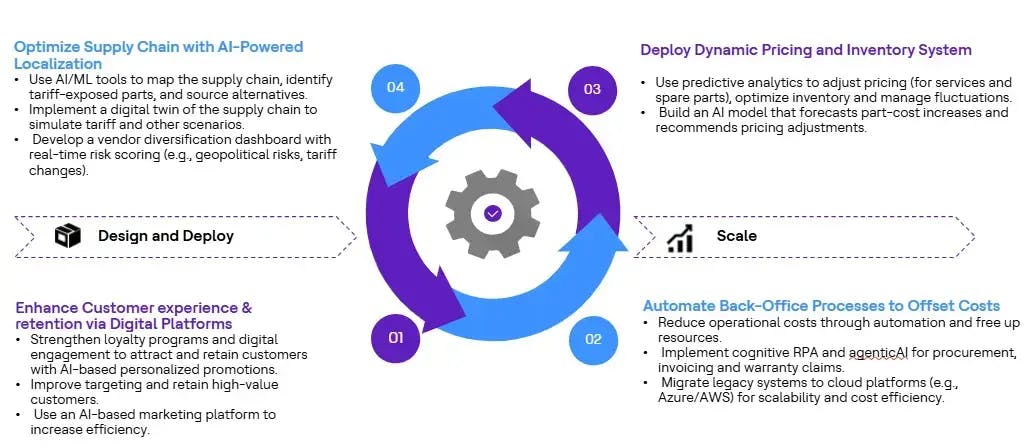

To address these challenges and capitalize on opportunities, service providers can implement several innovative strategies. Here are some key solutions:

Enhance customer experience and retention via digital platforms

Strengthening loyalty programs and digital engagement through personalized AI-based promotions can attract and retain customers. Improving targeting to retain high-value customers using AI-based marketing platforms can increase efficiency and drive growth.

Automate back-office processes to offset costs

Reducing operational costs through automation can free up resources for more strategic initiatives. Implementing cognitive RPA and migrating legacy systems to cloud platforms like Azure or AWS enhance scalability and cost efficiency.

Deploy a dynamic pricing and inventory system

Using predictive analytics to adjust pricing for services and spare parts can optimize inventory management and minimize fluctuations. Building an AI model that forecasts part cost increases and recommends pricing adjustments is crucial.

Optimize supply chain with AI-powered localization

AI and ML tools can map the supply chain, identify exposed parts and source alternatives. Implementing a digital twin of the supply chain to simulate various scenarios can provide real-time insights. Developing a vendor diversification dashboard with real-time risk scoring (e.g., geopolitical changes) ensures resilience against unexpected changes.

In conclusion, understanding and navigating the impact of changing market conditions on the automotive aftermarket supply chain is essential for strategic planning and long-term success. By implementing these strategies, companies can adapt to changing market conditions, optimize operations and enhance customer experiences, positioning themselves for success in a competitive landscape.