IT infrastructure forms the backbone of enterprise technology, encompassing physical servers, virtual machines, applications, software, network switches and other components that keep digital environments running smoothly. On the other hand, OT (Operational Technology) infrastructure powers the physical world—comprising hardware and software that directly control and monitor industrial processes, such as PLCs, HMIs and robotics systems.

IT and OT industries follow different solution architectures. IT infrastructure is typically designed for a short-term lifecycle of 1 to 5–7 years. This is because upgrades become essential after this period and IT systems are inherently flexible and scalable, enabling organizations to adapt quickly to new opportunities and industry changes.

On the other hand, OT infrastructure is built for long-term goals, often lasting 5 to 15–20 years. The initial setup and development costs are high, as OT systems focus on critical operations in industries like manufacturing, energy and transportation. This design ensures reliable and stable performance for many years.

The Push for IT-OT Convergence

Over the years, there has been a growing demand for IT and OT convergence. Integrating these domains offers significant benefits to customers, such as improved efficiency and data-driven insights. However, this convergence also introduces challenges. Below are some common issues IT and OT teams face when collaborating. However, we will also talk about the solutions of such challenges further:

IT/OT convergence presents several challenges:

- Integration of technologies: Combining IT and OT systems can be complex due to different behavior in its solution design, standards and architectures.

- Cybersecurity risks: Merging IT and OT increases the attack surface, making robust cybersecurity measures essential.

- Cultural differences: Aligning the priorities and workflows of IT and OT teams, which traditionally operate in silos, can be difficult.

- Data interoperability: Ensuring seamless data exchange between IT and OT systems requires significant effort and coordination.

- Scalability issues: Scaling converged systems while maintaining performance and reliability can be challenging.

How to facilitate IT/OT convergence

When building joint goals of IT/OT convergence, manufacturers should consider few main areas:

- Safety. Keeping people safe and happy are an essential goal for both IT and OT teams. For example, reliance on existing tools/resources is often more valued than a new digital tool that takes too long to learn and slows down production floor data flow.

- A goal to lead their industry. We should encourage teams to be the first to tackle problems that other companies are unable to figure out how to solve. Working together, IT/OT can achieve what has never been done before. This will give birth to innovations in both the industries and in turn consecutive wins can be seen.

- Togetherness. Focus should also be on gaining employee trust by working on culture shifts, acceptance of new tools/softwares. This will highlight the power of collaboration.

- Security. OT systems are increasingly targeted by cyber-attacks, which can lead to significant disruptions, data breaches, and financial losses. IT Teams can help OT by leveraging the Cyber Resilience offerings for end-to-end security.

In addition to these shared common goals, there are specific ways that both OT and IT teams can move their company’s Industry 4.0 forward.

IT and OT Components

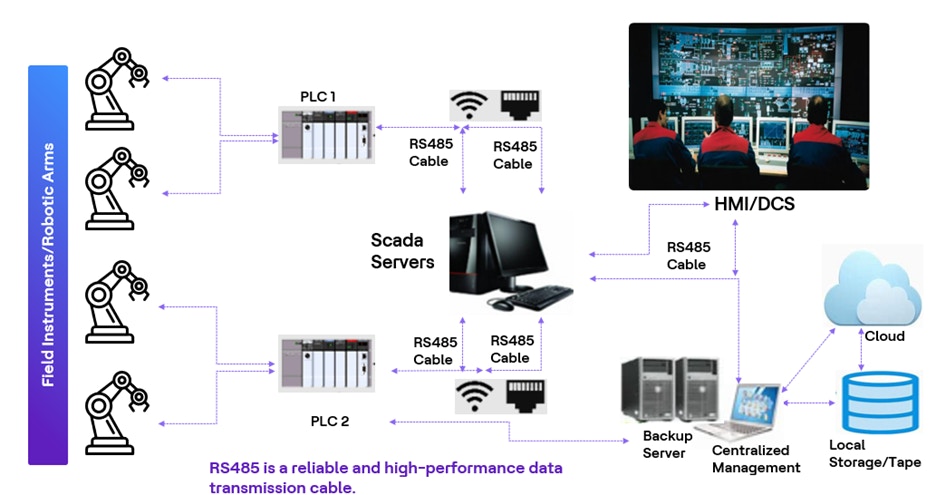

OT Components | Purpose |

Industrial Control System (ICS) | Heart of industrial automation, ICS includes SCADA systems, DCS and programmable logic controllers (PLCs) |

Distributed Control System (DCS) - Monitor and control physical devices | |

Programmable Logic Controller (PLC)- Industrial Grade Digital Computer designed to perform control functions for industrial applications | |

Supervisory Control and Data Acquisition (SCADA) collects data from various sensors at a factory or plant and then processes this data in a central system. | |

Human Machine Interface (HMI) | It is the workstation for the human operator, displaying process data in real time |

Sensors and actuators | Sensors collect real-time data (temperature, voltage, current, wind direction) Actuators translate control signals into physical actions (turn on/off equipment such as motors, pumps). |

Historian server | Industrial DB- stores and logs data collected from various parts of the industrial network |

IIoT devices | Connected devices to collect and transmit data from industrial machines and processes |

IT Components | Purpose |

Servers | Web servers, DB servers, email servers, directory services, virtualization servers, security and many more |

Network devices | Switches, routers and firewalls to direct n/w traffic and ensure communication b/w devices |

Engineering workstation | It plays a crucial role in various industries, especially for professionals who handle intensive workflows |

Storage devices | Hard drives, SSD and SANs |

Security s/w | Antivirus, anti-malware, and intrusion detection systems |

IT/OT Convergence explained through illustration

How IT teams can support OT

IT teams can play a crucial role in supporting OT teams during IT/OT convergence by focusing on several key areas:

- Collaboration and communication: Establishing effective communication channels between IT and OT teams is essential. Regular meetings and joint planning sessions can help align goals and ensure both teams are on the same page.

- Unified data management: IT teams can assist in creating a unified data infrastructure that allows seamless data exchange between IT and OT systems.

- Training and skill development: Providing training for OT staff on IT systems and vice versa can help bridge the knowledge gap. This can include workshops, cross-functional training programs and certifications.

- Standardization and interoperability: IT teams can help standardize protocols and ensure interoperability between different systems and devices. This reduces complexity and enhances the efficiency of integrated operations.

Summary

The convergence of IT and OT is not just a technical challenge; it requires a cultural transformation. Both teams must overcome differences in mindset, bridge knowledge gaps, and enhance communication to foster a mutual understanding of their roles and responsibilities. Leadership plays a critical role in driving this change. Whether they are senior managers or passionate advocates for incremental progress, identifying and empowering these leaders is only the first step. Success depends on equipping both IT and OT teams with the right resources, skilled talent and financial backing to sustain collaboration and deliver measurable outcomes