Introduction

In today’s rapidly changing industrial landscape, organizations are under increasing pressure to improve operational efficiency, reduce costs and meet sustainability targets while adapting to fast-paced technological advancements. Traditionally, this adaptation has relied heavily on historical data and controlled physical testing, which can be both time-consuming and expensive. To address the need for efficiency, cost savings and sustainability, industries must integrate a digital-physical ecosystem where virtual simulations (digital twins) seamlessly merge with real-world operations. It opens new possibilities on how we visualize, simulate and interact with physical spaces in an immersive virtual environment.

Business challenge

HCLTech, in collaboration with AWS, aims to transform industrial operations by integrating digital twins, virtual replicas of physical assets, systems or processes, with real-time operational data. This integration allows industries to:

- Simulate real-world scenarios and predict outcomes

- Make data-driven decisions in real time

- Test strategies cost-effectively

- Enable proactive maintenance

- Optimize resource use

Ultimately, this drives operational excellence, reduces downtime, cuts costs and supports sustainability through intelligent, risk-free innovation.

Solution approach

HCLTech MetaTwin is a spatial computing solution built on the AWS cloud. It is an advanced metaverse collaboration platform that combines immersive XR visualization with powerful digital twin technology to transform real-world industries. Accessible through XR devices and the web, MetaTwin allows customers to easily build and deploy industrial metaverses. The platform integrates leading AWS services, including AWS IoT TwinMaker, IoT SiteWise and Amazon Bedrock, alongside advanced XR capabilities, providing a strong foundation for creating customized digital twin ecosystems.

Features of MetaTwin:

Functional realms for every industrial need

MetaTwin offers specialized realms designed to meet diverse industrial needs.

- Industry realm: Collaborate in a digital twin of manufacturing plants with live OT/IoT data for real-time insights.

- Virtual Co-Pilot: Leverage a GenAI-powered virtual assistant within the metaverse to analyze operations data and the document based manuals and SOPs for actionable recommendations.

- Training realm: Engage in immersive, interactive Virtual training sessions, including equipment assembly/disassembly or worker safety trainings.

- Solutions realm: Virtual presentation space to host your customers and any stakeholders and showcase any solutions and product demonstrations.

- Meeting realm: Conduct virtual meetings with integrated presentation tools for seamless collaboration.

- Avatar creation: Customize your digital identity to enhance presence in the metaverse.

Built for collaboration

MetaTwin supports multi-user collaboration across training, simulations, inspections and design reviews, fostering seamless teamwork and enhanced engagement regardless of physical location.

Immersive and intelligent visualization

- Digital twin visualization: Deliver immersive spatial experience of digital twins with operational insights powered by cutting-edge digital twin technology.

- 3D content streaming: Seamlessly render complex CAD models in high fidelity, reducing load times and improving visualization.

- Real-time environment loading: Instantly access dynamic environments such as factories, construction sites and refineries, enabling rapid decision-making.

- Immersive content: Integrate PLM systems, CAD data, XR SDKs and personalized avatars to create an engaging, collaborative experience.

API-Driven 3D Asset Integration

MetaTwin’s API-driven architecture enables seamless integration of 3D models and assets, enhancing multi-user collaboration with rich interactive features and real-time animations.

Web and content integration

Users can access external websites directly within the metaverse, interact with dashboards and view content like PDFs and PowerPoint presentations—without leaving the platform.

GenAI-powered virtual assistant

A built-in GenAI assistant retrieves information from manuals, protocols and SOPs. It can answer FAQs, guide troubleshooting and provide contextual support—making it a true digital co-pilot.

Secure and connected

MetaTwin ensures a secure, real-time connected environment using blockchain and a mix of wired, wireless and 5G technologies.

Industrial data analytics

Built-in visualization tools empower users to create dynamic charts, graphs and immersive visualizations, transforming complex industrial data into actionable insights that drive smarter operations.

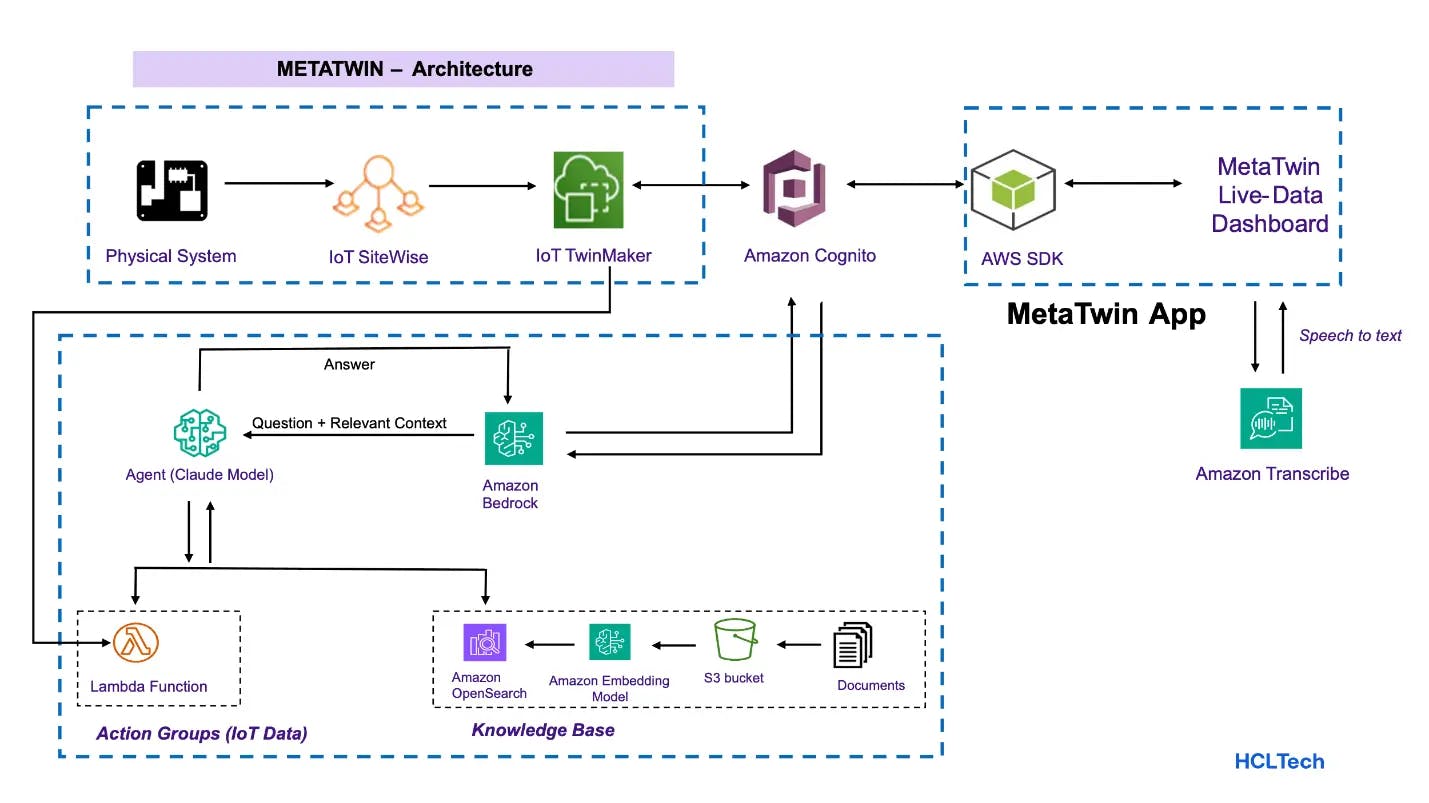

MetaTwin logical architecture (Industrial realm)

MetaTwin’s architecture integrates physical assets, edge connectivity, cloud services and human access layers to deliver a comprehensive digital twin ecosystem.

Bridging the physical and digital worlds

At the foundation lies the physical world, encompassing factories, plants, equipment and infrastructure. This real-world data is funneled into two distinct digital twin layers:

- Digital twin as designed (virtual data): Captures static design information such as CAD models and factory layouts, enabling advanced visualization, physics simulation and predictive modeling

- Digital twin as operational (real-time data): Integrates live IoT and OT data via edge connectivity and cloud services, delivering actionable real-time insights and analytics

Human-centric interaction

MetaTwin prioritizes human-centric interaction, enabling intuitive access to the digital twin via XR devices, mobile apps, web portals and even emerging brain-computer interfaces—ensuring seamless engagement across all user roles and environments.

Solution Components

Core Architecture

The platform integrates several AWS services to create a robust, scalable and secure experience. These services include Amazon Bedrock for AI applications, AWS Lambda for serverless computing, and IoT SiteWise and TwinMaker for industrial data management. Additionally, Amazon Cognito provides secure user authentication, while Transcribe converts speech to text. For scalable storage, the platform utilizes Amazon S3 and OpenSearch enables fast data retrieval.

Data Flow Process

From physical systems to digital twins

At the heart of the Industrial Realm of MetaTwin lies the physical system, which could be anything from a manufacturing line to a smart building. This system streams telemetry and operational data into AWS IoT SiteWise, a managed service that collects, organizes and monitors industrial equipment data at scale.

From there, AWS IoT TwinMaker takes over, creating a digital replica of the physical environment. This twin provides a contextualized view of assets, processes and relationships—essential for real-time monitoring and simulation.

Secure access and real-time dashboards

To ensure secure user authentication and access control, Secure authentication with Amazon Cognito combined with AWS SDK powers the MetaTwin Live-Data Dashboard, delivering real-time visibility and control over digital twin data.

Conversational intelligence

MetaTwin features conversational intelligence that transforms spoken input into actionable insights, powered by AI models hosted on Amazon Bedrock. This makes interactions natural, intuitive and efficient.

Knowledge integration

The intelligent agent connects knowledge bases and real-time IoT data through AWS embedding models and action groups, enabling precise, context-aware responses that enhance decision-making.

- Knowledge base uses AWS embedding models to convert documents in Amazon S3 into searchable vectors, enabling the agent to retrieve relevant information from manuals and guides

- Action groups provide real-time access to IoT telemetry via AWS SiteWise and IoT TwinMaker, allowing the agent to respond to live operational data

To ensure accurate and context-aware responses, we apply prompt engineering and implement a Retrieval-Augmented Generation (RAG) approach. This customizes the LLM to generate answers grounded in both static documents and dynamic IoT data.

Solution Benefits

MetaTwin empowers enterprises and manufacturers with a suite of benefits that redefine how they operate, collaborate and train:

- Enhanced collaboration: Immersive 3D visualization enables remote walkthroughs and teamwork, overcoming geographical barriers.

- Optimize design and planning cost: Virtual environment allow to validate the design in a collaborative way reducing design defects and better decision making.

- Operational efficiency: Provides the virtual remote operation center allowing plant / factory technicians to monitor and control real time operations avoiding any downtime.

- Workforce training efficiency: XR-based training reduces time and eliminates physical infrastructure needs.

- Predictive insights: Real-time monitoring and AI-driven maintenance minimize downtime and cut costs.

- Intelligent assistance: AI-powered virtual co-pilots boost workforce productivity and decision-making.

- Sustainability: Virtual validation instead of physical prototypes, Reducing travels and optimized resources contribute to greener operations.

Ready to revolutionize your industrial operations?

- Schedule a demo: Experience MetaTwin firsthand. Book a personalized demonstration to see how our platform can address your specific industry challenges.

- Consult with our experts: Do you have questions? Our team of industrial metaverse specialists is ready to discuss your unique needs and how MetaTwin can drive innovation in your organization.

Conclusion: Shaping the future of industrial innovation

MetaTwin is more than technology. It’s a transformative platform reshaping how industries harness data, collaborate and innovate. By merging real-time IoT, immersive 3D environments and AI-driven intelligence, MetaTwin enables businesses to unlock unprecedented operational agility, smarter decision-making and sustainable growth. As industries evolve, MetaTwin will lead the charge—empowering organizations to thrive in the era of the Industrial Metaverse.