The mining industry can greatly benefit from the implementing digital twin technology. By driving adoption at scale, businesses can enhance performance, boost efficiency, mitigate risks, and cut down costs. Given the rapid pace of technological advancements, it is evident that Digital Twin technology has immense potential and will continue to gain traction in the mining sector.

Digital technologies are one of the key pillars that have revolutionized the present landscape of manufacturing. Rising uncertainty and the globalization of businesses are shifting present entrepreneurs to invest in technologies that can drive value and give them a competitive advantage over their peers.

Recently, the new face of digital twin technology has emerged as a pivot in achieving the aspirations of manufacturing business leaders.

In the aluminium industry, digital twin processes can be leveraged to drive efficiencies (cost, quality and time), performance, productivity and efficiencies of cost, quality and time.

Overview

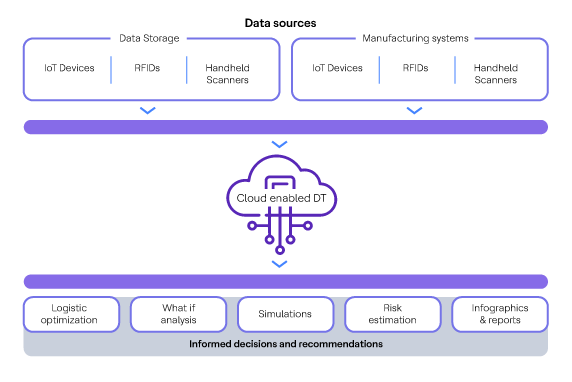

A Digital Twin is a high-precision, digital representation of a physical world such as a process, object, or system. It combines the power of real-time data captured from various sources, such as sensors & systems, with the physical records containing information about design specifications to imitate the behaviors of the physical world. With the advent of enormous computing power through cloud infrastructure,

Digital Twins, with the help of statistical models, can now run virtually any number of simulations in real time to generate insights and recommendations for shopfloor employees. A Digital Twin can be a digital shadow (1:1 copy) or digital thread (trends, simulations, correlations, predictions, etc.)

1. Simulations/what-if outcomes

In the aluminum industry, Digital Twin technology can be used to create virtual replicas of complex processes and run various probable simulations and what-if scenarios before making any actual changes in the physical world. It helps real-world situations in a controlled environment without any human interventions analyze real-world situations in a controlled environment without human interventions. With this approach we can optimize various key parameters without even making any changes in the real process parameters. This way we can not only test ample numbers of test outcomes but can also predict the optimum setting for various desired outcomes.

Potential applications: Pot Digital Twin, Furnace Digital Twin at Cast House.

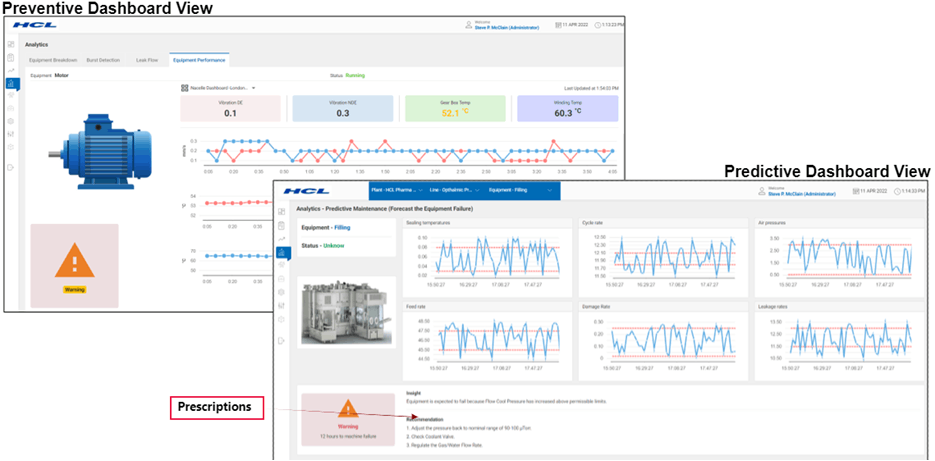

2. Predictive maintenance

For any typical manufacturing industry, unscheduled breakdown not only adds more manhours spent for the uptime of assets but also incurs an additional cost burden on their respective cost centers. Therefore, early detection and proactive rectification of such stoppages is one of the key drivers for maintenance personnel to aim for Digital Twin technology. With Digital Twin in place for their assets, an employee can pre-empt the possible defects and rectify them before it leads to a production halt. By continuously monitoring data gathered from sensors & systems, the Digital Twin can help the Cast House personnel to take informed decisions and save costs. Digital Twin model has many other advantages such as remote monitoring, diagnosing and preventing potential failures & aid in remote operation.

Potential application: Monitor and report cranes fleet such as pot tending machines in real-time, health monitoring of vibro compactor machine, rectifier’s assets uptime

3. Quality control

Rework and defective pieces are two of the critical aspects in aluminum manufacturing. With continuous monitoring and integrating data from various sources, implementing digital twins will generate insights and recommendations for various process parameter settings, ensuring the outcome is the desired product with the expected specifications. Digital Twin uses machine learning algorithms to identify patterns and correlations that is hindering the quality aspect of the final product. With this technology a manufacturer can adhere to the quality standards expected by the end consumers.

Potential application: Carbon block’s specifications

4. Sustainability

Since aluminum industry is an energy-intensive industry, a significant portion of the production goes towards power generation. Therefore, every aluminum manufacturer is aiming to be more energy efficient and sustainable. At the core. a Digital Twin runs various scenarios to determine optimum process parameters and sends recommendations to have an energy-efficient process, optimizes resources and reduces waste.

Potential applications: Monitoring HF emissions from fume treatment plant, Monitoring GHG emission at green anode plants

5. Supply chain

Digital Twin technology has also its footprints in supply chain. A Digital Twin can be leveraged for logistic optimization and inventory management. In a supply chain Digital Twin, a virtual model is created incorporating all the stakeholders from suppliers till end consumers. A holistic view of all the data collected from each of stakeholders is created and analyzed using various statistical models. Based on the best outcome, the manufacturer enforces the best practices to optimize logistics and inventory management.

In summary, the benefits of digital twins in mining include improved performance and efficiency and reduced risks and costs. As mining technology is growing at such an unprecedented rate, the potential of implementing digital twin technology is likely to gain more and more traction in the manufacturing sector.