Powering Everything from Smartphones to Autonomous Vehicles

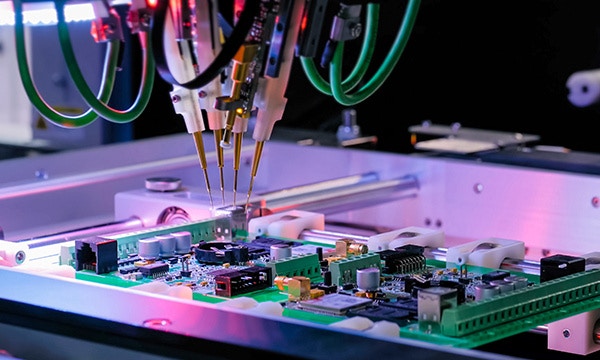

The semiconductor industry's growth is fueled by the demands of AI, 5G and IoT. As the need for more efficient and complex devices rises, HCLTech draws on more than two decades of semiconductor expertise to deliver advanced services.

Our strategic partnerships with leading OEMs, fabs and chip companies help us address industry challenges with a comprehensive suite of solutions — spanning mechanical and electrical engineering, software development and semiconductor design. This holistic approach lets us offer end-to-end semiconductor manufacturing services tailored to diverse client needs, with quality assurance and testing at every step.

Why Choose HCLTech for Your Semiconductor Needs

Years of experience in semiconductor domain

Of the top 10 semiconductor equipment OEMs are our clients

Engineers working for top 13 global OEMs and 3 of the top 4 ISVs

Design partner for major foundries – Intel, Samsung, TSMC, GF

Engineers driving R&D breakthroughs

Tapeouts across multiple foundries/nodes

Semi-chip Design Capabilities

Design services

Our semiconductor design services cover product architecture, microarchitecture, RTL design and design verification — ensuring efficient and reliable hardware implementations.

Package design services

We offer routability feasibility analysis, PLOC definition, bonding diagrams and substrate layouts to optimize performance in semiconductor production.

Test manufacturing services

Our services include memory BIST, wafer sort testing, probe card and load board design, yield monitoring and test program optimization.

Semiconductor validation services

We provide essential testing and verification for semiconductor technologies — including pre-silicon validation, process corner characterization, wake-up and functional validation and volume validation.

Qualification services

We ensure thorough testing for packaging solutions with temperature cycling, HTSL, UHAST and HTOL qualification. Our team handles design reviews, fabrication and socket solutions for burn-in boards and burn-in vector development.

Manufacturing services

Our manufacturing services span prototype and risk production — setting up manufacturing flows and creating bills of materials (BOM). Volume manufacturing focuses on supplier management, material monitoring and ongoing quality assurance.

Semi-equipment OEM Services (Explore more)

Mechanical and manufacturing engineering services

Expertise in equipment subsystems engineering: product design services, ECN/ECO, automation, NPD, VAVE, cost reduction, obsolescence, sourcing, EOL management and prototyping.

Electrical engineering services

Specialists in system design, product refresh, control and power electronics. We bring expertise in ECO, BOM, NPI, test validation, obsolescence engineering and more.

Software engineering services

We deliver software development, validation, control system software, sustenance engineering, L3 support, simulator development, test automation, DevOps, performance engineering and product testing.

Value-added services

Our clean room and ATE lab facilities support product development, AR/VR-based training, data analytics, AI/ML, DevOps, predictive maintenance, Industry 4.0, PLM on cloud, cybersecurity and sustainability.

Fab services

We offer fab operations, automation, cloud services, equipment testing, reliability testing, failure analysis, characterization, refurbishments and R&D — tailored to each client's needs.

Test engineering services

We focus on precision test program development, conversions, DIB and probe card innovations, test optimization and characterization.

State-of-the-Art Labs

HCLTech operates state-of-the-art labs across the semiconductor value chain, driving innovation and excellence from design to fabrication.

Silicon Tester Lab

Silicon Validation Lab

Wafer Handler Lab

Trends & Insights

Analyst Recognitions

HCLTech recognized as a Leader in Everest Group's Semiconductor Engineering Services PEAK Matrix® Assessment 2024

Learn moreHCLTech and Arm collaborate on custom silicon chips optimized for AI workloads

Learn moreHCLTech wins Intel’s 2024 EPIC Outstanding Supplier Award

Learn moreHCLTech recognized as a Leader in ISG Digital Engineering Services, 2024

Learn more

Testimonials

Ready to Take the Next Step?

Our semiconductor services lead the way, so let's talk.

Find what inspires and drives you

Frequently Asked Questions about Semiconductor Services

At HCLTech, we provide comprehensive semiconductor services covering the entire value chain—from product design and architecture to manufacturing, validation and quality assurance. With over two decades of experience, we deliver advanced semiconductor solutions tailored to each client’s needs, ensuring innovation, reliability and accelerated time-to-market for their products.

We help clients address challenges such as rapid innovation cycles, complex chip design, manufacturing scalability, quality assurance and time-to-market pressures. Leveraging deep domain expertise, advanced automation and strategic partnerships, we enable clients to overcome technical hurdles, reduce costs and maintain a competitive edge in semiconductor production and design.

Yes, we offer comprehensive RTL design, validation and packaging design services. Our teams handle everything from RTL development and verification to routability analysis, bonding diagrams and substrate layout. This integrated approach ensures seamless development, robust quality assurance and smooth transitions from design to manufacturing for our clients.

Our testing services span memory BIST, wafer sort, probe card and load board design, yield monitoring and test program optimization. We also offer pre-silicon validation, process characterization, functional and volume validation and qualification testing to ensure every device meets rigorous performance and reliability standards before reaching the market.

We leverage AI and GenAI to accelerate chip design and testing by automating specification analysis, test case generation and design verification. Our proprietary GenAI solutions streamline test code generation and validation workflows, helping clients achieve faster development cycles, improved accuracy and reduced costs throughout the semiconductor lifecycle.

Our semiconductor services support a wide range of industries, including automotive, consumer electronics, telecommunications, industrial automation, healthcare and more. We work closely with OEMs, fabs and technology companies, delivering solutions that power everything from smartphones and autonomous vehicles to advanced medical devices and industrial equipment.

Our semiconductor design services stand out through end-to-end ownership, from architecture to tapeout and a proven track record across analog, digital and mixed-signal domains. We combine deep technical expertise with advanced automation, GenAI tools and close industry partnerships, ensuring efficient, reliable and high-quality hardware implementations for our clients.

Absolutely. We have the expertise and resources to take full ownership of the chip design process, from product specification through to tapeout and qualification. Our “Spec to Platform” approach covers front-end and back-end design, validation, prototyping and manufacturing, delivering turnkey semiconductor services and solutions with accountability at every stage.

Our validation services ensure product quality with thorough pre-silicon and post-silicon testing, process corner characterization and functional validation. We use state-of-the-art labs and proven methodologies to identify and resolve issues early, ensuring each chip performs reliably in real-world conditions and meets all client and industry requirements.

We ensure timely delivery through a combination of advanced automation, digital twin technology and robust project management. Our deep expertise, proven methodologies and global engineering resources allow us to optimize every phase of semiconductor services—from design to production—helping clients meet aggressive market timelines without compromising on quality or reliability.

Contact Us

Subscribe to the HCLTech Newsletter

for our latest news and insights