Revolutionizing e-mobility with a cost-effective Vehicle Control Unit (VCU)

Overview

A leading British electric drivetrain specialist, recognized for its innovative electric motor technology, sought to enhance its offerings for OEMs. By developing a Vehicle Control Unit (VCU) for its EV drive line, the client would enable customizable, scalable and cost-effective eDrive solutions tailored to specific applications. HCLTech leveraged its deep expertise in digital engineering and e-mobility to co-develop the VCU across hardware, software and mechanical domains, ensuring compliance with ASIL-C safety standards and aligning with the client's electrification goals.

The Challenge

Overcoming complexities in developing a VCU

As the demand for electric vehicles (EVs) surged, the client needed to overcome the following hurdles to accelerate the VCU development:

- Stringent safety and time constraints: Achieving compliance with rigorous safety standards (ASIL-C) within tight deadlines

- Resource dependency: Limited supplier support increased reliance on internal resources

- Component procurement: Issues with sourcing critical components such as the Hardware Security Module (HSM) library and microcontroller

- Cost management: Escalating costs due to resource and component limitations, hence threatening project viability

The Objective

Building a scalable, modular and secure VCU

The client sought a technology partner with proven expertise in digital engineering and e-mobility to drive innovation and expedite the development timelines. At HCLTech, our unwavering commitment to innovation positions us as a trusted partner of choice. Our objective was to deliver a VCU architecture that would be:

- Scalable: Accommodating various LEV configurations with minimal design adjustments, enabling broad adaptability

- Modular: Facilitating quick replacements and upgrades of hardware and software components

- Safe: Meeting stringent ASIL-C safety standards with robust validation processes

- Secure: Incorporating advanced cybersecurity features, including a Secure Bootloader and HSM integration

- Cost-effective: Reducing overall development costs by streamlining component sourcing, including custom MCAL driver development

The Solution

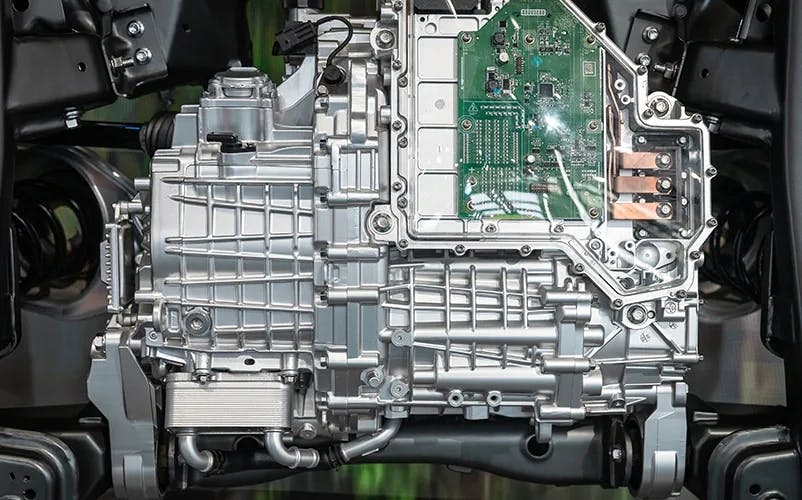

End-to-end development of hardware, software and casing for the VCU

We delivered a comprehensive solution that spanned hardware, software and mechanical design, enabling seamless integration into the client’s EV ecosystem. Key contributions included:

- Hardware design: Developed prototype boards and conducted pre-compliance testing for electrical systems, Electromagnetic Compatibility (EMC) and End-of-Line (EOL) requirements.

- Mechanical design: Designed an IP67-rated casing compliant with ISO 16750 standards, ensuring durability in harsh environments

- Custom software development: Created Non-AUTOSAR-based MCAL drivers and a Secure Bootloader with Updater, providing a cost-efficient alternative to off-the-shelf solutions

- Software integration: Integrated MATLAB-compatible vehicle software and tested for seamless performance

- Agility in development: Adapted to changing requirements by adding functionalities such as XCP on CAN for real-time calibration and parameter updates

- Collaboration across domains: Ensured cross-functional coordination between hardware and software teams for end-to-end project success

The Impact

Propelling the client’s VCU program to new heights

HCLTech’s collaboration with the tier-1 supplier revolutionized their VCU development program, driving operational efficiency and enhancing market readiness. Key outcomes included:

- Cost reduction: Achieved 80% cost savings through in-house Secure Bootloader development.

- On-time delivery: Maintained a 100% on-time delivery rate over two years, improving customer satisfaction metrics

- Cost optimization: Enabled flexible catalog pricing, reducing procurement complexity

- High First-Time Right (FTR) score: Delivered consistent quality with minimal rework, boosting operational efficiency

- Scalable and modular architecture: Delivered customizable VCU architecture, enhancing its adaptability for diverse LEV applications

- Enhanced functionality: Optimized performance of critical vehicle functions, including accelerators, brakes and motor units

Building on the success of the VCU program, the client aims to develop a scalable software platform capable of supporting multiple variants, enabling further customization and innovation. This initiative underscores HCLTech’s commitment to driving industry transformation through cutting-edge engineering and e-mobility solutions.