Accelerating intelligent manufacturing and engineering with HCLTech and Intel

A global mobility leader modernized its device infrastructure with HCLTech, Intel and Lenovo, deploying AI PCs to drive smart manufacturing, AI-led development, and sustainable operations.

Overview

A global technology leader in mobility solutions sought to modernize its device infrastructure to support smart manufacturing, AI-driven product development and sustainable operations. Partnering with HCLTech, Intel and Lenovo, the organization deployed AI PCs powered by Intel® Core™ Ultra processors across engineering, IT and operations teams worldwide. This initiative enabled AI at the edge, enhanced product lifecycle management and advanced the client’s vision of becoming a software-defined mobility leader.

The Challenge

- Increasing demands for AI-driven workflows in manufacturing and engineering

- Relying on legacy endpoints that limited productivity and edge AI enablement

- High cloud dependency created latency and security concerns for sensitive workloads

- The scale and diversity of global teams made device management and adoption complex

The Objective

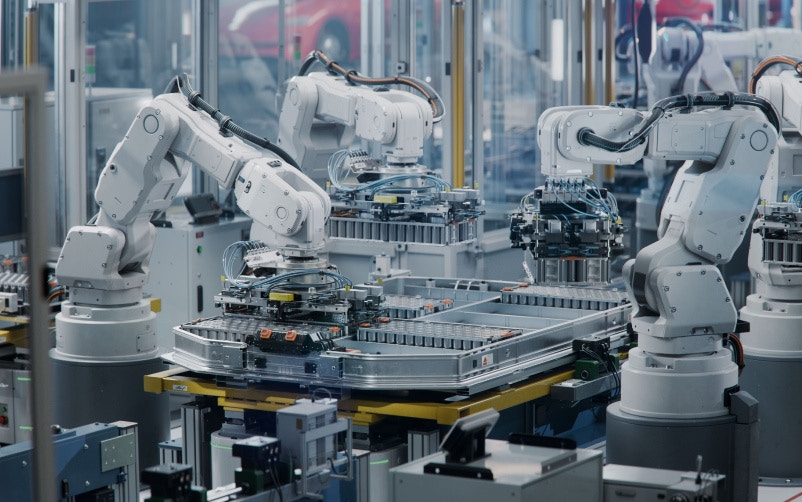

- Accelerate AI adoption in product lifecycle management, predictive maintenance and factory automation

- Enhance workforce productivity with intelligent, secure and manageable endpoint devices

- Reduce cloud dependency by enabling edge inferencing and AI capabilities locally

- Ensure seamless, large-scale deployment and adoption across multiple geographies and user personas

The Solution

- HCLTech led the persona-driven rollout of Lenovo AI PCs powered by Intel® Core™ Ultra processors integrated with Neural Processing Units (NPUs) and Intel vPro® for manageability and security

- The deployment included Intel Endpoint Management Assistant (EMA) for remote device control and Microsoft Copilot for productivity enhancements

- Extensive AI enablement was provided via tailored training and local generative AI inferencing using Intel OpenVINO™

- The solution encompassed engineering, manufacturing, IT and corporate functions, enabling use cases from CAD automation to digital twin-based predictive maintenance

The Impact

- Up to 15% reduction in design iteration time; reduced manufacturing rework

- 15–20% decrease in routine support tickets

- >50% Copilot adoption within the first 90 days

- 15% reduction in downtime incidents

- 25–30% of AI workloads offloaded to local device

Intel services used

- Intel® Core™ Ultra processors with integrated AI capabilities

- Intel vPro® Platform

- Intel Endpoint Management Assistant (EMA)

- Intel OpenVINO™ toolkit