Next-gen GBS

The most powerful driver of change in this fast-growing digital world is the idea of bringing organizations closer to the customer.

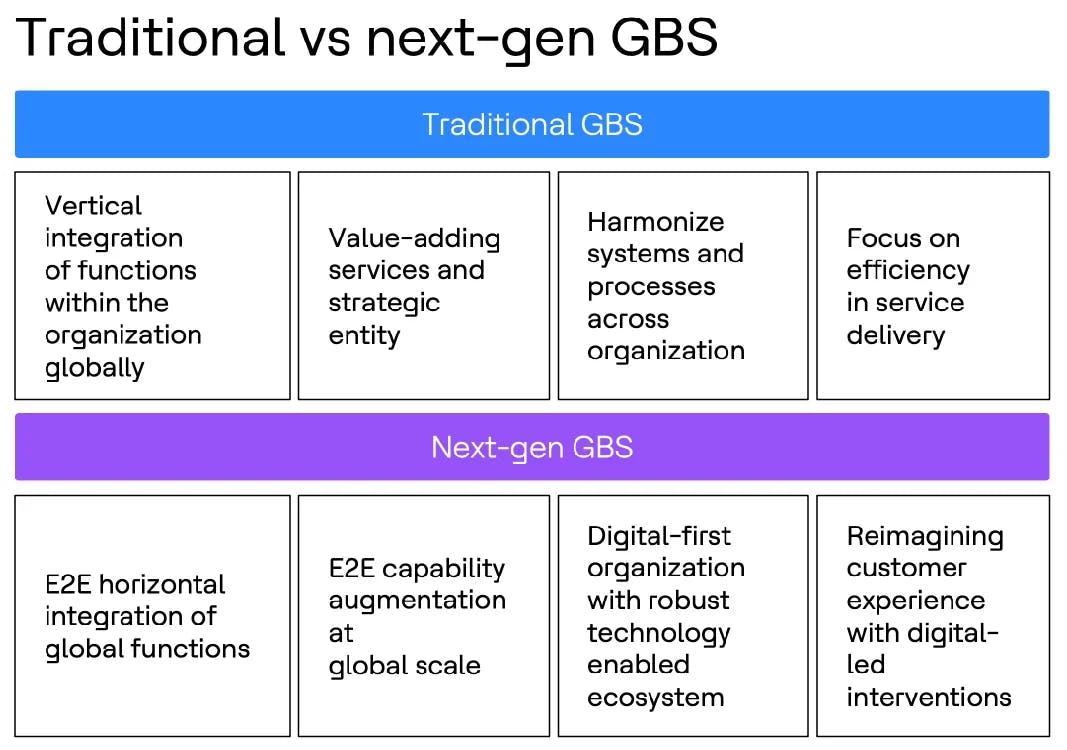

There are four key driving forces behind the next-gen GBS evolution compared to the traditional GBS model.

- Realignment from the vertical integration of functions like HR, Finance, Supply Chain, Sales, etc., to the horizontal integration of multi-service, end-to-end process-owned organizations like Order to Cash, Source to Pay, Record to Report, etc.

- Transition from value-added services to functional excellence through capability enhancement beyond back-office operations

- Paradigm shift from harmonization/standardization to process intelligence-driven automation and transformation

- Next-gen GBS focuses on adopting technologies like Generative AI, Large Language Model (LLM), Internet of Things (IoT) and Blockchain to drive enhanced customer experience through predictive and prescriptive analytics

Supply Chain in next-gen GBS

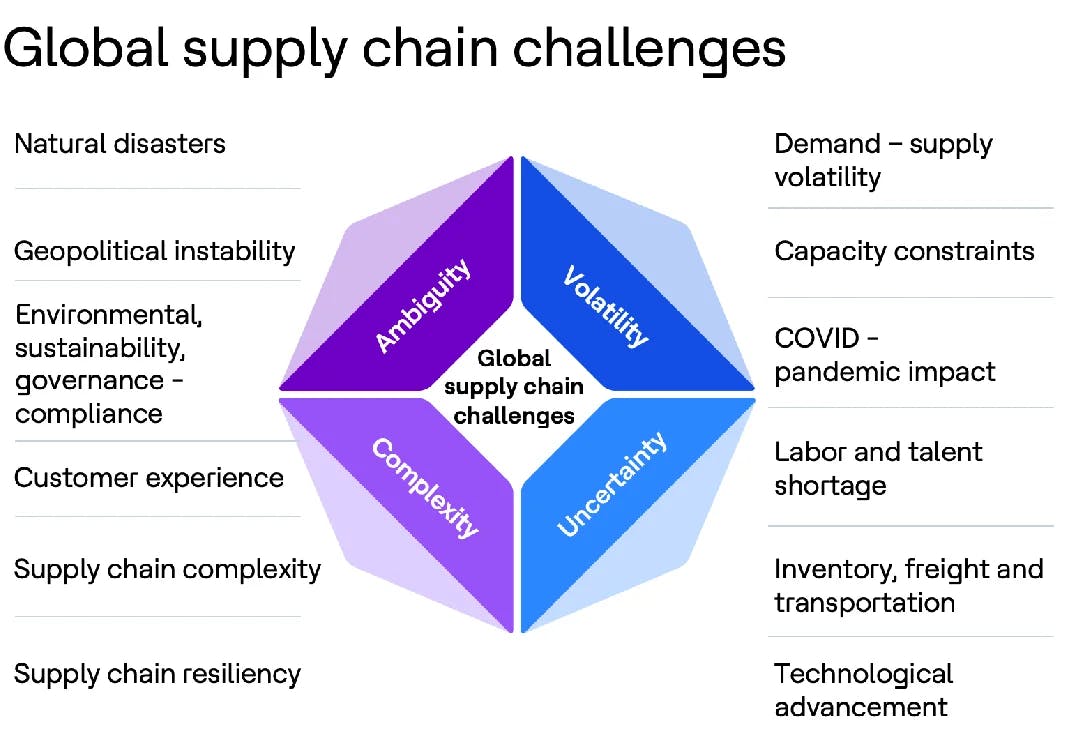

In the supply chain world, the well-known acronym VUCA (volatility, uncertainty, complexity, ambiguity) has never been more relevant than it is today. So, innovative strategies with best-in-class change management are the need of the hour to address some of the challenges and evolve the supply chain in line with the new operational landscapes. Next-gen GBS focuses on key supply chain functions such as order management and customer service, sourcing and procurement, supply chain planning, inventory management, logistics network planning and distribution for value creation and cost reduction through centralization, digitalization and automation. As per a survey conducted by one of the leading research firms, with more than 200 companies from different sectors, 46% of supply chain activities now reside in the GBS space, with a deliberate focus on transitioning to 75%+ over the next 2 to 3 years. The value created through the next-gen GBS setup is enormous and companies want to tap into it at as soon as possible.

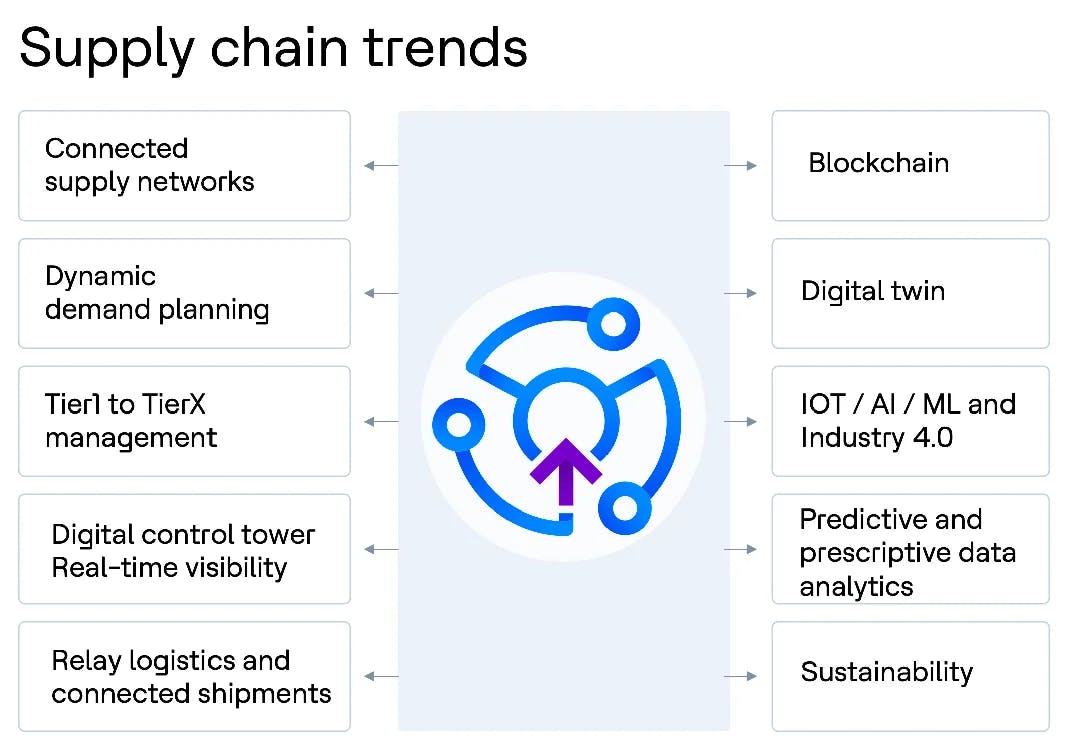

Below are key digital-driven concepts and technologies designed in the next-gen GBS operating model that make the supply chain more resilient.

Top 5 SCM success levers in next-gen GBS

- Enhanced visibility and control: Next-gen GBS models operate on a global scale, making it essential to have real-time visibility into supply chain processes. SCM solutions provide comprehensive insights into inventory levels, on-time delivery, production status, market pricing, transportation and other critical aspects of the supply chain. This granular visibility allows GBS organizations to identify bottlenecks, optimize processes and make informed decisions, thereby gaining better control over their operations. Supply chains generate big data, and cloud-based AI turns that data into insights. Cloud computing, coupled with AI, has transformed how supply chains operate using intuitive control towers. Through predictive analytics, cloud and AI systems can use past trends and market indicators to provide complete E2E visibility and enable data-driven decision-making.

- Resilient supply chain operating mode: Supply chain disruptions are inevitable, especially in a global context. Effective supply chain management (SCM) empowers organizations to quickly adapt to changing market conditions, shifts in demand and unexpected disruptions. Global operations entail various risks, including geopolitical, economic and environmental factors. Next-gen GBS models help in assessing and managing risks in the supply chain by analyzing at the enterprise level (by country, plant, business group and Supplier up to Tier N). Organizations can proactively address challenges, adjust their strategies, sourcing, and distribution methodologies promptly, minimize disruptions and ensure business continuity, ultimately leading to improved resilience.

- Improved efficiency and cost savings: Supply chain optimization is closely linked to cost efficiency. Next-gen GBS models can leverage SCM practices to streamline processes, eliminate inefficiencies and reduce operational costs. This optimization includes inventory management, demand forecasting and transportation routing. Optimizing these processes enables organizations to achieve significant cost savings while maintaining high-quality services. In the procurement space, delivering significant cost savings has always been the ask. So, maintaining a detailed supplier repository guides the sourcing and category managers to get better spending visibility across the value chain. A centralized data framework, complemented by an analytics engine, helps decision-makers identify high-priced or low-performing suppliers. Should-cost modeling, tail spend management, total cost of ownership, contractual management, category strategy and vendor consolidation are effectively performed in the next-gen GBS operating model to drive savings at an enterprise level.

- Enhanced customer experience and services: A Harvard Business Review revealed that, on average, it costs organizations 6 to 7 times more to acquire a new customer than retain an old one, and a 5% reduction in customer defection can increase profits by up to 95%. Improved customer satisfaction is paramount to reducing customer defection, and “on=time delivery” plays a key role in achieving this. Next-gen GBS organizations enhance customer experience through accurate order fulfillment (on-time-in-full, or OTIF), reduced delivery times and improved product quality. Meeting customer expectations contributes to brand loyalty and positive reviews, further driving business growth. A supply chain CoE setup will enable improved customer experience by developing pointed strategies, creating the roadmap for achieving excellence and improving CSAT.

- Maximizes ROI on tech investment and common platforms: Next-gen GBS models often invest in digital technologies and common platforms to streamline operations. Effective SCM implementation maximizes the return on these investments by integrating technology solutions across the supply chain. This integration enables seamless data sharing, process automation and real-time analytics, driving better decision-making and optimizing the use of technology resources.

Achieving supply chain excellence in next-gen GBS

Next-gen GBS strives to turn the organization’s supply chain into a competitive advantage by aligning supply chain deliverables with customers' Service Level Objectives (SLO). This involves not only setting quantitative metrics for delivering speed and accuracy but also integrating qualitative measures that reflect customer satisfaction and feedback. Embracing such a customer-centric approach ensures that every link in the supply chain contributes to a positive and memorable customer journey. Enterprises must re-evaluate their delivery models through the lens of customer-centricity and redesign them to optimize processes for efficiency, reliability and flexibility, all while keeping customer needs at the forefront.

As businesses expand their operations, addressing the challenge of scale becomes increasingly critical. The design of supply chains must not only accommodate higher volumes but also maintain the agility necessary to navigate shifts in demand, regulatory dynamics and unforeseen disruptions. This is where advanced technologies come into play, serving as indispensable tools for realizing these objectives.

Moreover, harmonizing people, processes and technology unlocks the potential to harness scale and integration. This, in turn, yields valuable outcomes in terms of operational effectiveness, reduced time-to-market and enhanced performance metrics.

GBS will continue to focus on performance, increased digitalization, delivering value through advanced insights and analytics and hyper-automation with a customer-first approach.

Why HCLTech?

HCLTech’s forward-thinking approach harnesses the power of next-gen GBS to revolutionize supply chain pathways, driving unparalleled efficiency, agility and excellence. Our commitment to redefining supply chain pathways is elucidated below:

- From the back office to strategic supply chain functions: In addition to the traditional GBS services, HCLTech is delivering strategic functions for our clients in demand planning, strategic sourcing and category management, supplier management, inventory management, customs and logistics, driving cost-saving and operational efficiency. We can streamline operations, reduce cost and manage growth/variability while improving services. The quality-of-service delivery and expertise built into the shared services enable your organization to extract business value and release working capital.

- Next-gen GBS enterprise navigator module: This module consists of the below capabilities, which help in assessing an organization’s current process maturity and recommending the future state operating model aligned towards next-gen GBS transition.

- Process maturity assessment

- Organization effectiveness assessment

- Golden process design recommendation

- Future-state organization design

- HCLTech’s SCM Solutions Portfolio “FLOYD”: Possesses a suite of rapid solutions modules that solve key operational problems and improve visibility through an intuitive and powerful user experience. This provides a holistic view of supply chain operations with the underlying principles of “Sense-Alert-Act.”

By embracing HCLTech’s suite of services, enterprises can position themselves at the forefront of innovation and achieve supply chain excellence. We ensure that every facet of your supply chain aligns with customer expectations. Our expertise in re-designing delivery models optimizes economies of scale, empowering organizations to drive efficiency and maximize value creation, now and well into the future.

Discover how HCLTech can reimagine your supply chain management. Click here to learn more.