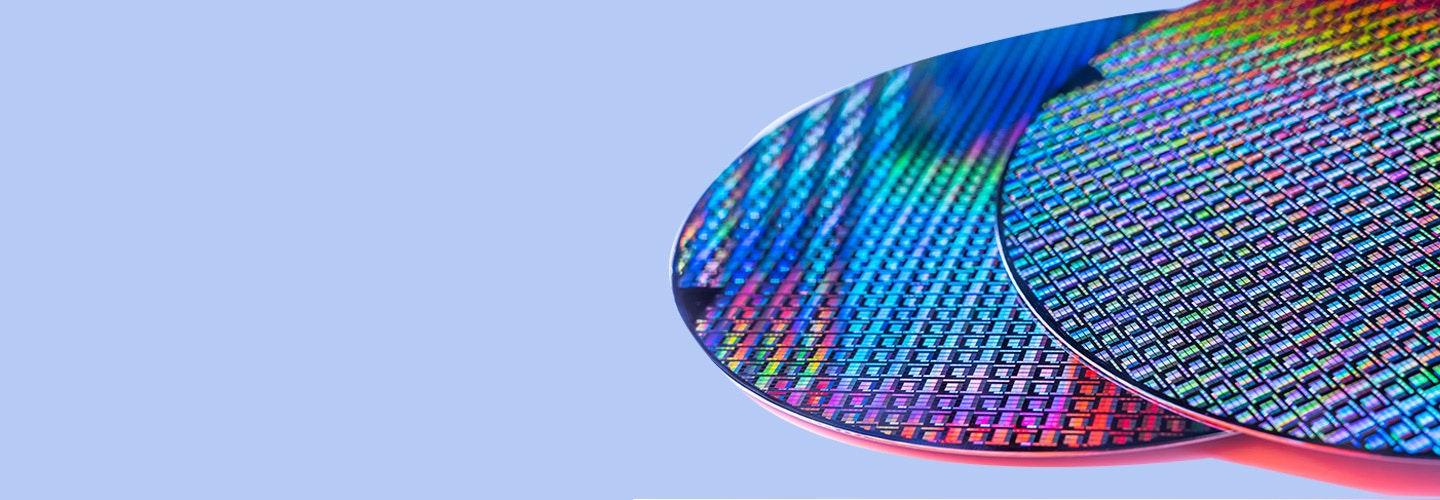

ML-driven beam optimization for high-yield semiconductor performance

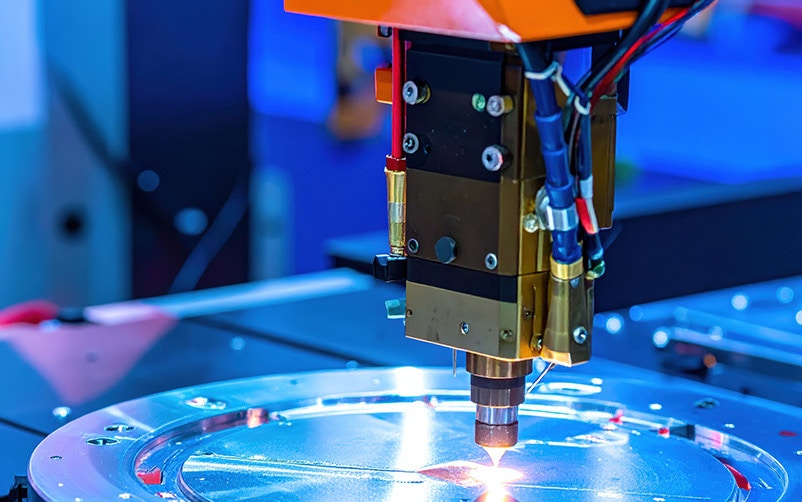

Our client is a global leader in semiconductor manufacturing equipment, known for its cutting-edge ion implantation technology used in wafer processing. As the industry continues to demand precision and performance, the client sought to modernize its beam parameter tuning process to reduce manual intervention and improve efficiency.

To achieve this, the client partnered with HCLTech to develop an intelligent system that leveraged machine learning to accurately predict beam parameters and streamline implantation operations. The initiative aimed to boost overall yield, reduce operational overhead and modernize legacy systems without disrupting ongoing production cycles.

The Challenge

Optimizing operations within complex, legacy-bound environments

The client’s existing AutoTune system could generate beam tuning parameters, but often failed to converge within set iterations. This led to frequent manual overrides, increasing engineering workload and compromising operational efficiency. Several key challenges hindered transformation:

- Operational inefficiencies: Incomplete convergence created workflow interruptions and inconsistent results.

- Data limitations: A small dataset (fewer than 1,500 records) restricted model training quality.

- Legacy constraints: Development was constrained by a Windows XP environment with no external cloud access.

- Tool availability: Limited access to physical ion implantation equipment delayed model testing and validation.

The client needed a smarter, more autonomous solution that could perform accurately within these constraints and integrate seamlessly into its legacy environment.

The Objective

Autonomous beam parameter tuning for higher efficiency and yield

The goal was to build a reliable, ML-powered system that could:

- Eliminate the need for manual tuning

- Minimize beam tuning errors

- Increase equipment throughput and process yield

- Operate efficiently within restricted computing environments

- Reduce dependence on physical tool availability for validation

The Solution

ML-powered automation and prediction system for high-accuracy tuning

To address the challenges, our team of experts designed and implemented a comprehensive machine learning-based solution tailored to the client's needs. The goal was to create a smarter, more accurate way to predict beam parameters and reduce manual tuning.

- Intelligent prediction models: Built 14 dedicated machine learning models — each focused on predicting a specific beam parameter — using regression algorithms and deep neural networks.

- Smart data handling: Carefully prepared training data by removing anomalies (like doubly charged recipes) and using median values to improve model accuracy and performance.

- Modular deployment approach: Packaged the solution as an independent application using Flask and Docker, allowing easy rollout and integration into the client’s existing systems via REST API.

- Legacy system integration: Delivered a fully functional solution that operates within the client’s existing XP-based infrastructure, without the need for external cloud support.

- Model monitoring and retraining: Monitors, analyzes model performance and continuously learns with new data

- Improved operational efficiency: The result was a streamlined process that enhanced predictive accuracy, minimized manual effort and supported a more efficient, autonomous workflow.

The Impact

From manual bottlenecks to intelligent, autonomous performance

By aligning deep engineering expertise with cutting-edge technology, we successfully transformed a traditionally manual, error-prone process into a streamlined, intelligent system. The solution not only resolved long-standing operational inefficiencies but also unlocked significant improvements in productivity, reliability and yield, reinforcing the client's leadership in semiconductor manufacturing.

The collaboration delivered measurable outcomes that demonstrate the tangible business value of our ML-driven transformation approach:

- 90% reduction in wafer implantation interruptions caused by beam parameter errors

- Near-elimination of manual intervention, reducing operational overhead and human error

- Significant yield improvements as a direct result of accurate beam tuning

- Validated proof of concept, demonstrating the potential of machine learning in high-precision, legacy-bound industrial environments

This engagement underscores our ability to engineer impactful, future-ready solutions, even in the most constrained and complex operational landscapes.