The automotive industry is in the midst of an unprecedented transformation, driven by the dual forces of electrification and the advent of Software Defined Vehicles (SDVs). The software-defined vehicle market itself is projected to grow from USD 213.5 billion in 2024 to USD 1,237.6 billion by 2030 at a CAGR of 34.0% (Markets and Markets, 2025).

This profound shift is reshaping the competitive landscape, compelling Original Equipment Manufacturers (OEMs) to pivot from a long-standing hardware-centric approach to one where software proficiency dictates innovation and market leadership. As the global automotive market, valued at over $3.5 trillion in 2023, is predicted to exceed $6.8 trillion by 2033 with a CAGR of 6.77% (Spherical Insights, 2024), this transition presents both immense opportunities and significant challenges.

The rise of Electric Vehicles (EVs) is reshaping the very foundation of automotive engineering. From vehicle architecture to design approaches and validation processes, demanding new competencies across the board. Simultaneously, the rapid evolution of connected vehicles, now integrating advanced technologies like 6G, transforming automobiles into intelligent systems that enhance everything from traffic safety to the overall driving experience.

In this new landscape, software has become the core driver of innovation. The ability to rapidly develop, deploy and update software functionalities will be the key differentiator for success in this evolving automotive landscape.

The role of AI in automotive engineering

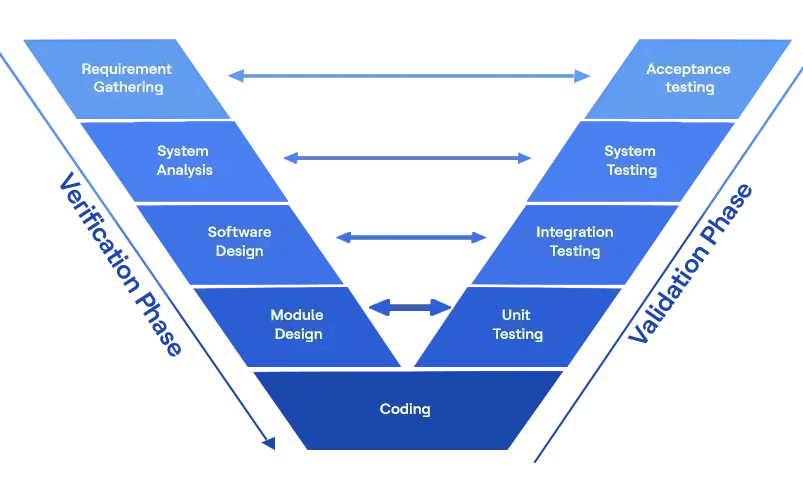

Artificial intelligence (AI), especially Generative AI (GenAI), is playing a transformative role in automotive design and manufacturing. It significantly enhances efficiency, innovation and safety in modern vehicle development. AI and GenAI can be applied across the V-model within vehicle development. This includes improving the design process by accelerating requirements definition and optimizing verification and validation through rapid analysis and testing of components, assemblies and entire vehicles. AI is also used to develop new models, predict customer preferences and improve autonomous driving capabilities.

Fig 1: V model in vehicle development

Leading technology providers are leveraging GenAI models, tools and technologies to accelerate product development, improve quality assurance and enhance data analytics. This strategic adoption of AI leads to optimized processes for maximum efficiency, higher quality and reduced costs throughout the software engineering lifecycle.

The importance of ALM tools in the SDV era

Application Lifecycle Management (ALM) tools are crucial for automotive OEMs, especially in their Smart Vehicle strategies. With the shift towards SDVs, ALM solutions are essential for managing a vehicle's entire lifecycle, from development to disposal. These tools standardize collaboration across software teams and other departments, enabling automated software development and deployment, which shortens the time from product conception to market launch and reduces costs.

While the leading Individual Software Vendors (ISVs) are bringing out the standardized ALM platforms, technology providers like HCLTech are developing solutions that enhance the capabilities of COTS ALM platforms using modern technologies like GenAI.

One such GenAI-based solution is HCLTech xLMate, designed for platforms like PTC Codebeamer and Siemens Polarion. The solution boosts productivity by automating quality analysis, subsystem requirement generation, test case creation, translation and summarization of requirements. It evaluates requirement quality based on International Council on Systems Engineering (INCOSE) guidelines, identifying ambiguities, inconsistencies and other issues to ensure well-defined requirements. HCLTech xLMate also supports the generation of requirements across all levels with traceability to reference data and can automatically generate test cases based on defined requirements, accelerating testing and ensuring comprehensive coverage. Furthermore, it facilitates global collaboration by supporting the translation of documents into multiple languages and can summarize long documents for quicker approval.

Another key solution is HCLTech SwiftX, which supports customers in their digital transformation from requirement definition to the entire vehicle development process. SwiftX assists with the migration of existing ALM solutions, whether COTS-based or custom-built, reducing the complexity of this process by providing a robust technology platform that addresses common migration challenges.

The power of integrated approach

The complexities of the modern automotive landscape demand more than fragmented services. A truly comprehensive approach, built on the synergy between deep technical expertise and specialized industry knowledge, offers a distinct advantage. HCLTech, renowned for its engineering expertise in xLM and digital design and ASAP Group, with its strengths in critical verification and validation, creates an end-to-end portfolio.

This integrated ecosystem provides a holistic view and seamless execution across the entire vehicle development lifecycle, from initial concept to final validation. Such comprehensive coverage, translates into several key advantages for automotive manufacturers navigating this transformative era:

- Accelerated market entry: By leveraging advanced technologies, including GenAI, the development cycle can be significantly streamlined, enabling faster introduction of innovative vehicles and features to the market.

- Enhanced efficiency and quality: The integration of decades of industry experience and specialized domain knowledge helps minimize rework and optimize processes, leading to higher quality in both hardware and software, ultimately enhancing user experience and customer satisfaction.

- Optimized resource utilization: Scalability and flexibility inherent in such integrated solutions contribute to lower operational costs, allowing OEMs to allocate resources more strategically.